Main points of construction of broiler chicken cages

With chicken market increasingly competitive, and farmers modernization consciousness gradually improve, more and more farmers to standardization, scale breeding mode, build the henhouse chicken farming became the caged equipment now farmers choose mode of breeding, so farmers in the building of the hen house should be how to build?

1. Site selection: avoid intensive farming areas with better water quality.

2. Feeding mode: cage raising in two stages: "raising young" and "laying eggs".

3. Chicken battery cages construction: it is recommended to raise 15,000 to 20,000 chickens per chicken coop, adopt closed chicken coop and broiler cage feeding equipment, cement floor, wall white cement batch white, automatic drinking water, feeding, ventilation, manure cleaning, etc.

First, the overall layout of the chicken farm:

1. General principles: from the perspective of facilitating epidemic prevention and organizational production. The divisional layout of the field area is the production area, office area, living area, auxiliary production area, and sewage treatment area.

2. Arrangement principle: According to the dominant wind direction, the topography and the flow direction are the living area, office area, auxiliary production area, production area and sewage treatment area. If the terrain is inconsistent with the wind direction, the dominant wind direction is dominant.

Second, the layout of the chicken farm: the overall plan should consider the factors such as the orientation of the chicken house, the spacing of the house, the road, sewage, fire prevention and epidemic prevention. The recommended design of 100,000 large-scale chicken farms is recommended to be arranged in 6 single or double row chicken houses. The single chicken house is 16,000 closed chicken houses. It is equipped with four rows of four aisles and three-tiered ladder cages. Curtains, ventilated windows, mechanical cleaning, mechanical feeding and automatic lighting, automatic drinking water system.

1. Single-roof house orientation: It adopts east-west or east-north (or west) 15 degrees, which is conducive to improving the winter temperature and avoiding summer solar radiation, using the dominant wind direction to improve the ventilation conditions of the house.

2. Chicken house spacing: two types of single-row houses and double-row houses. The spacing of the chicken houses is 10 to 20 meters for brooding and 10 to 15 meters for laying hens.

3. Chicken farm road: The chicken farm road is divided into two types: clean road and dirty road. The clean road is used for transporting feed, chicken and eggs in the field. The dirt is used to transport manure, dead chicken and sick chicken. The two must not be used interchangeably.

Suitable Humidity and Temperature for Raising Chickens

Humidity is closely related to evaporation of water in the chicken body when they are raised in poultry equipment cages, body heat emission and cleanliness of the house are very important.

When the temperature is high and low humidity, the water in the chicken is not dispersed too much, which may lead to dehydration of the chicks. In addition, due to drying, the dust inside the house is flying, and it is easy to induce respiratory diseases.When the temperature is low and high humidity, the house is cold and humid, and the chick is prone to cold, causing the litter to be wet, and the gastrointestinal disease occur. In general,when the temperature is high and high humidity, the heat in the chicks is not easy to be emitted normally, suffocating, appetite is falling, growth is slow, and resistance is weakened.

The laying house of the laying hens should be kept dry to prevent bacterial growth and infection, but the relative humidity should not be lower than 40%. Suitable relative humidity is 60% -65% before 10 days old and 50%-60% after 10 days old in your poultry farm equipment house.

Method of mixing feed for broiler chicken breeding in broiler cage

In the process of developing poultry farming projects in broiler chicken cages, it is hoped that the nutrients contained in each feed that chickens eat are balanced. Otherwise, the flock will suffer from malnutrition, nutrient deficiency or poisoning. Therefore, the feeding formula of the chickens in the automatic broiler cage can be stirred evenly to meet the nutritional needs of the chickens.

There are two methods of feed mechanical mixing and manual mixing. As long as it is used properly, satisfactory results can be obtained.

- The broiler cage feed is mechanically mixed, using a broiler cage mixer. Commonly used broiler cage mixers are vertical and horizontal.

The vertical mixer is suitable for mixing powdered feed with a water content of less than 14%. If the water content is too high, it is difficult to mix evenly. This kind of broiler cage mixer requires small power and is easy to maintain, but the mixing time is long (generally 10-20 minutes per batch), which is suitable for chicken farmers and small chicken farms.

The horizontal mixer can mix the broiler cage feed evenly in areas with relatively humid climates or when strong viscous ingredients (such as grease) are added to the feed. The machine has a short mixing time, 3-4 minutes per batch, and is mainly used in some feed processing plants. No matter what kind of broiler cage mixer is used, in order to stir evenly, the charging amount must be appropriate. Too much or too little charging cannot be uniform. Generally, 60%-80% of the capacity is suitable for charging. The mixing time is also an important factor related to the mixing quality. The mixing time is too short, but it is not the longer the better. If the mixing is too long, the feed will be mixed evenly and then cause stratification due to excessive mixing.

- Manual mixing is the main method of feed mixing when raising chickens at home.

When mixing, be careful and patient to prevent some trace ingredients from clumping and agglomerating. Uneven mixing will affect the feeding effect.

When manually mixing chickens in battery cages for broiler, special attention should be paid to some trace components that account for a small proportion in the diet but will seriously affect the feeding effect. Such as salt and various additives. If the mixing is not uniform, the feeding effect will be affected in the light, and the chickens will be poisoned or even die in serious cases.

For such trace components, the broiler cage feed must be fully crushed when mixing, and there should be no agglomeration. The agglomerates may be poisoned after being eaten by the chickens. Secondly, due to the small amount of such ingredients, they cannot be directly added to bulk feed for mixing, but should be pre-mixed.

The method is: take 10%-20% of the concentrate (which is a large proportion of energy feed, such as corn) as a carrier, and stack it in addition, and press the feed of the next shovel on the feed put down by the previous shovel, that is, go all the way to the feed. The feed is placed on the top, and the feed flows around the center point to form a cone, so that various broiler cage feeds have the opportunity to mix. Repeat this 3-4 times to achieve the purpose of mixing evenly, and the premix is ready. This premix is then added to the whole feed and mixed 3-4 times in the same way to achieve the purpose.

Broiler Breeding Technology in Chicken Farm

More and more farmers are beginning to develop the breeding industry. Large-scale breeding of chickens requires the use of Poultry Rearing Equipment, such as broiler cages, dung removal equipment and feeding equipment. However, in addition to these breeding equipment, if you want to raise chickens well and bring economic benefits to yourself, you still need certain breeding technology. The following are the key points of broiler breeding technology.

First of all, large-scale farming requires a farm. We need to know where is the best place for chicken farm construction. The selection of chicken farm site is directly related to the epidemic prevention status and economic benefits of chicken farms. According to the size of the breeding scale and the resource conditions, it is necessary to have a clear view of the convenient transportation of the chicken coop, sufficient water resources and guarantee the power supply. Electricity is required for lighting, water supply, temperature supply, ventilation, etc. in the chicken farm, so the chicken farm requires sufficient power supply. Environmental conditions are good and there is room for development.

Chicken coops are places where chickens live healthily. When building chicken coops, attention should be paid to the performance of heat preservation, heat insulation, ventilation and lighting, moisture prevention, ease of production and operation, disinfection and epidemic prevention, etc. At present, there are many types of buildings in chicken coops, which can be divided into two categories: open type and closed type according to different building structures and performances. Closed henhouse is also called windowless henhouse, because it is relatively closed to the outside world, has the function of temperature isolation and shading, and can adjust and control the internal environment of the henhouse. It has greater advantages than open henhouse, but it has high cost and large infrastructure investment.

Broilers for meat are more suitable for high-density feeding, and the feeding amount depends on the effective feeding area of the chicken house and the appropriate feeding density in battery cage for chickens. However, in actual production, the amount of breeding is restricted by many factors. The first is the number of breeders, the second is the feed supply capacity and the source of chickens, and the third is the area of chicken houses. Under the condition that there is no problem with the first two, the feeding amount depends on the area of the chicken coop.

There are two types of ventilation in chicken coops: mechanical ventilation and natural ventilation. There are mainly two types of mechanical ventilation in closed chicken coops, namely, horizontal ventilation and vertical ventilation. These are the key points of raising chickens in the poultry house, hoping to help farmers build a suitable chicken farm.

Do you Know What’s the new Concept of Broiler Rearing Management?

With the progress of the times and the development of science and technology, the genetic breeding technology of broilers has been greatly improved, and the nutritional formulation of chicken feed has also undergone new changes. Broiler breeds are constantly being optimized, and the feeding and management viewpoints of broiler chickens are no longer practical. The broiler breeders at this time need to understand some new ideas for the early feeding and management of broilers.

Do a good job of early feeding chicks, so that the chicks get even and good development in the first week. Changing the way that chickens were fed before drinking water for a period of time before they were fed will become better when the chicks arrive. Change the practice of distributing drinking fountains according to the number of chickens in the past, and increase the number of drinking fountains accordingly so that the chicks can easily find the water in the column after entering the house. If the chicks do not use the trays within the first day of arrival, use clean plastic cloths on the net or spread clean and hard papers to spread the material on the chicks for feeding. The effect is much better than using the trays alone.

Precautions for purchasing broiler cages in Nigeria

Many farmers are purchasing broiler cages. Pay attention to some purchase matters.

First of all, we must know the distance between the iron bars of the broiler cage. This is very important for broiler cages. A reasonable spacing is 2.5cm*5cm. Some farmers may think that the size of the broiler chickens is relatively large, and the spacing can be increased. This idea is wrong. Conditional farmers can also lay a plastic net on the bottom of the broiler cage that is consistent with the cage eye. This can not only buffer the strength of the eggs hitting the net and reduce the rate of broken eggs, but also prevent some diseases.

The design angle of the bottom of the broiler cage. The angle of the broiler cage must be accurate. The egg cannot be rolled out in time at a small angle, and it is trampled by the chicken. A large angle may cause the egg to break, and the general angle is maintained at seven to eight degrees.

Pay attention to the connection between the broiler cage and the bottom of the cage net. I must remind you that there are farmers, and you can't leave a big gap here. Because there are more eggs here. You must pay attention to this detail when buying a broiler cage.

The choice of materials for the chicken cage is very particular. It is necessary to choose suitable and tough materials. The diameter of the iron wire at the bottom of the cage is about 2 mm. The egg breaking rate is very small. The larger the diameter of the iron wire, the easier it is to cause broken eggs.

Due to the high density of broiler cages, it is not conducive to observe the situation in the flock. Especially in the brooding period, it is more obvious, so it is necessary to carefully observe the cage around the cage carefully. Prevent the abnormal situation in the flock from being discovered and dealt with in time. When the chicks are just transferred to the rearing cage. Due to the new environment, the chickens will be temporarily uneasy. The chickens that ran out of the cage should be caught in the cage in time, and the chickens should be carefully checked for damage and whether all the chickens can drink water in time.

In addition, in daily management, we should carefully observe the chickens every time, and be well aware of the chickens’ feeding, drinking, feces, mental state, etc., timely prevent diseases, strengthen management, and reduce economic losses.These are the precautions for purchasing broiler cages in Nigeria

Analysis of the causes of chicken cold

Cooling is one of the main causes of chicken sickness. There are many cold spots. It is not only the temperature control level or the ventilation of the chickens, but the factors that can cause the chickens to be cold are as follows.

1. During the brooding, the water line is too low, the water pressure is too large, the chicks are drilled into the water cup, the nipple leaks, causing the chicken feathers to be wet; the spray equipment is damaged, the nozzle dripping seriously or the spraying time is long, causing the chicken feathers to be wet.

2. Improper humidification method, only pay attention to humidification, does not consider the temperature of the flock, when the flock performance temperature is low, humidification with a humidifying tube will make the flock cold.

3. The chicken house is not tightly sealed, causing side windows, sewage outlets, chicken outlets, water curtains, exhaust fan outlets, etc., resulting in thief winds, so that the chickens in this area are cold due to low temperatures.

4. After the wind enters the chicken poultry farming equipment from the air inlet, there are obstacles blocking during the pre-warming process, causing the breeze to rebound, and the chickens are swollen.

5. The temperature control is unreasonable; the cooling rate is faster, especially in the cold season, which makes the chicken's cold is more common.

6. Only rely on the temperature indicated by the thermometer, but the chicken's physiological behavior is not taken seriously, resulting in the chickens being cold.

How to Scientifically Avoid the Early Death of Chicks?

In many cases, because farmers do not properly grasp the knowledge of scientific feeding and management of chicken farms, it is easy to cause the early death of chicken farms, thus affecting the survival rate of chicks and further affecting the ultimate chicken efficiency. How do you scientifically avoid the early death of a chick when raising in poultry cages for sale.

Drinking water must be timely: especially after long-distance transportation of chicks, be sure to drink water in time, otherwise it will cause dehydration. Take a free drinking method and drink 5% of sugar water for the first time.

The temperature should be appropriate. The chicks are sensitive to temperature and maintain a 35-32 reduction trend within 1-3 weeks after hatching, increasing with age, and decreasing 2-3 times per week thereafter.

The density should be appropriate. if the brood density is too high, there will be more harmful gases in the house, and it will produce worms; the brood density is too small, the brooding area and equipment are not fully utilized, resulting in waste. The average density for flat raising is 20 per square meter, and 40-50 per square meter for cage raising.

More...

Reasons for dyspepsia in chicken houses

Nowadays, most farmers raise broiler chickens by using battery cage for broilers. It is convenient and quick to use automatic feeding equipment, and it also saves feed waste. But now, as the summer is about to pass, the autumn will follow, and the rain will be wet. Sometimes there will be a state of indigestion. In fact, there are many factors to consider for this problem.

Feed mold infection, mycotoxins can cause digestive diseases such as oral cavity, intestinal tract, causing indigestion, mycotoxin contamination including feeding mildewed feed, and pollution in processing, transportation and storage. Due to the hot weather, the oil is corrupted due to improper preservation, causing broilers to cause glandular gastritis, muscle erosion and enteritis. Free radicals or reactive oxygen molecules produced by fatty acids can affect their immunity, slow down growth, cause poor pigmentation and cause enteritis. Excessive fat addition can cause lubricative diarrhea.

The nutritional requirements of broilers are relatively high in chicken battery cages . The low content of crude fiber in the feed will result in unbalanced nutrition and excessive crude fiber, resulting in large feed intake of broilers and confusion of gastrointestinal function, which may also cause indigestion. Insufficient energy in the feed The broiler is eating for energy, not enough energy, increasing the feed intake of the broiler, causing other nutrients not directly absorbed and directly excreted, thereby causing indigestion.

It is necessary to know that broilers grow fast, especially the growth of internal organs is 35 days ago; because of the low anti-stress ability of broilers, the environmental requirements are higher. There is no regularity in broiler cage feeding, overeating, or stressing the chicken, or causing the chicken to experience low temperatures at a constant temperature, which can cause indigestion. 60% of broiler chickens are made of water, so there must be sufficient drinking water to meet the needs of the chickens, while some farmers do not pay attention to drinking water sanitation, drinking polluted water or degraded water, causing chicken indigestion.

What are the advantages of broiler cages?

Experiments show that the technical advantage of commercial broiler cages is significantly better than the flat to raise. Not only can increase the number of breeding, improve production performance, save production costs, bring significant economic benefits to farmers, but also save land resources, reduce environmental pollution, improve product quality, and create huge social benefits.

In recent years, a more advanced broiler breeding model, broiler cages, is quietly emerging. What advantages does broiler cages have?

The advantages of broiler cages are:

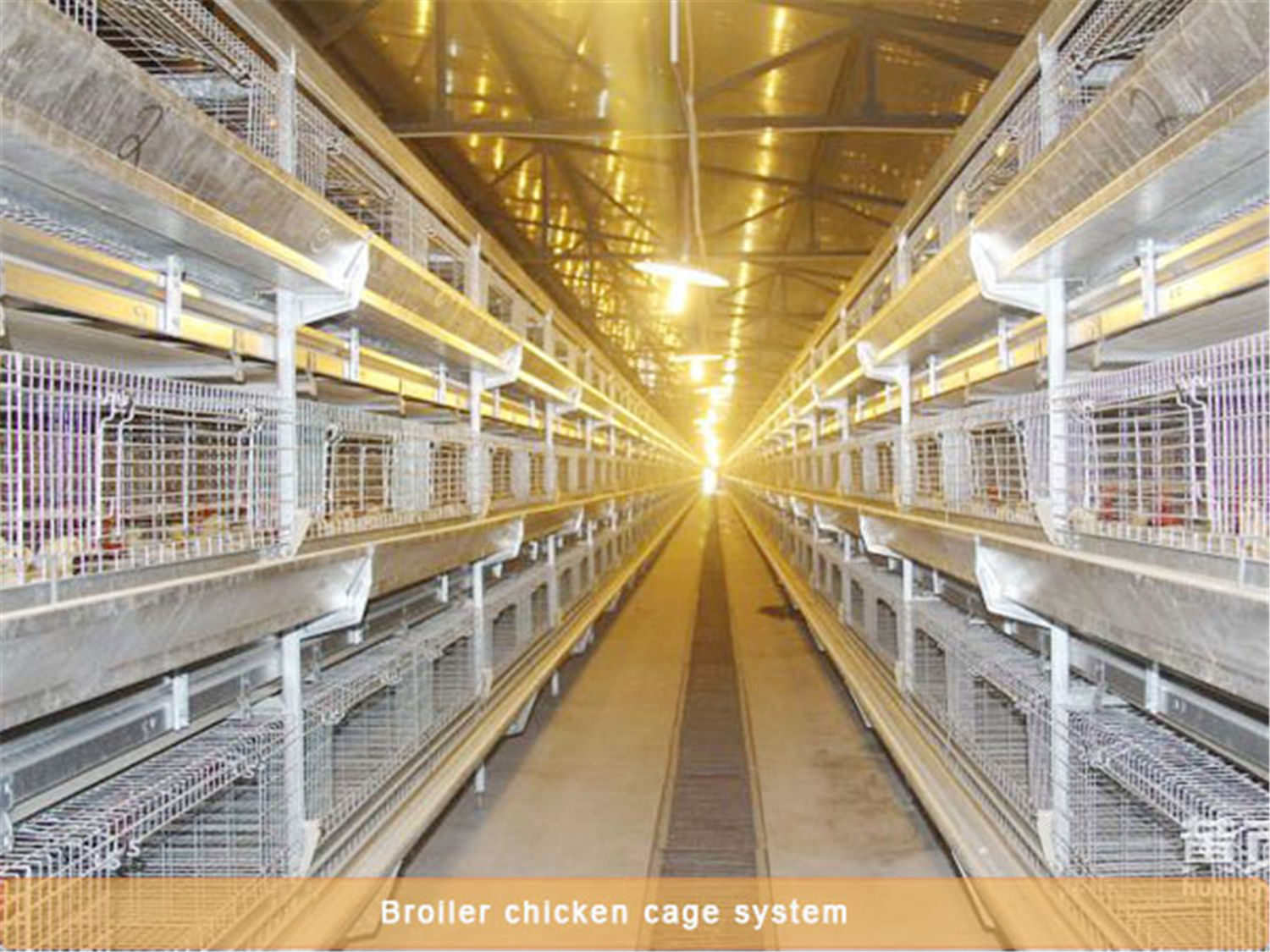

1. High level of automation: automatic feeding, drinking water, decontamination, wet curtain cooling, centralized management, automatic control, energy saving, reduced labor costs, greatly improving the breeding efficiency of farmers.

2. chicken flock prevention, effective prevention of infectious diseases: chickens do not touch the feces, can make the chickens grow stronger, provide a clean and warm growing environment for the chickens, the chickens are healthy and balanced.

3. Compared with the flat raise, the density of the stock is increased by more than 3 times, the utilization rate of the surface area of ??the house is improved, and the land can be saved.

4. Saving feed: meat cages increase the growth rate and feed conversion rate, chickens are kept in cages, the amount of exercise is reduced, energy consumption is less, and waste materials are reduced. According to the experiment, cage cultivation can effectively save more than 25% of the cost of farming. The ratio of feed to meat in net or flat chicken is generally between 1.75 and 1.8:1, while the ratio of caged meat to meat is at least 1.61:1 and the highest is 1.7:1.

5. Reduce the cost of medicines, at the same time can effectively control the occurrence of the disease, because the chicken does not touch the feces, and the use of closed houses, isolated from the outside, reduce the spread of disease; indoor comfortable environment is also suitable for the healthy growth of chicken.

6. Save time: It is convenient for breeding users to manage livestock and poultry, saving more time to deal with other things; using a fully enclosed and fully automated farming mode, two people can manage a chicken house with 3-4 million chickens, which is very economical. Artificial.

Therefore, on the whole, the advantages of cage farming benefit are more and more obvious. In the previous model of land raising and net broiler chicken, the profit of broiler farming was less and less, and many large-scale farming or group with funds, even small-scale Farmers have changed their own chicken houses into cages to further increase the scale and land utilization rate, and improve the breeding efficiency through scale effect.