Broiler Breeding Technology in Chicken Farm

More and more farmers are beginning to develop the breeding industry. Large-scale breeding of chickens requires the use of Poultry Rearing Equipment, such as broiler cages, dung removal equipment and feeding equipment. However, in addition to these breeding equipment, if you want to raise chickens well and bring economic benefits to yourself, you still need certain breeding technology. The following are the key points of broiler breeding technology.

First of all, large-scale farming requires a farm. We need to know where is the best place for chicken farm construction. The selection of chicken farm site is directly related to the epidemic prevention status and economic benefits of chicken farms. According to the size of the breeding scale and the resource conditions, it is necessary to have a clear view of the convenient transportation of the chicken coop, sufficient water resources and guarantee the power supply. Electricity is required for lighting, water supply, temperature supply, ventilation, etc. in the chicken farm, so the chicken farm requires sufficient power supply. Environmental conditions are good and there is room for development.

Chicken coops are places where chickens live healthily. When building chicken coops, attention should be paid to the performance of heat preservation, heat insulation, ventilation and lighting, moisture prevention, ease of production and operation, disinfection and epidemic prevention, etc. At present, there are many types of buildings in chicken coops, which can be divided into two categories: open type and closed type according to different building structures and performances. Closed henhouse is also called windowless henhouse, because it is relatively closed to the outside world, has the function of temperature isolation and shading, and can adjust and control the internal environment of the henhouse. It has greater advantages than open henhouse, but it has high cost and large infrastructure investment.

Broilers for meat are more suitable for high-density feeding, and the feeding amount depends on the effective feeding area of the chicken house and the appropriate feeding density in battery cage for chickens. However, in actual production, the amount of breeding is restricted by many factors. The first is the number of breeders, the second is the feed supply capacity and the source of chickens, and the third is the area of chicken houses. Under the condition that there is no problem with the first two, the feeding amount depends on the area of the chicken coop.

There are two types of ventilation in chicken coops: mechanical ventilation and natural ventilation. There are mainly two types of mechanical ventilation in closed chicken coops, namely, horizontal ventilation and vertical ventilation. These are the key points of raising chickens in the poultry house, hoping to help farmers build a suitable chicken farm.

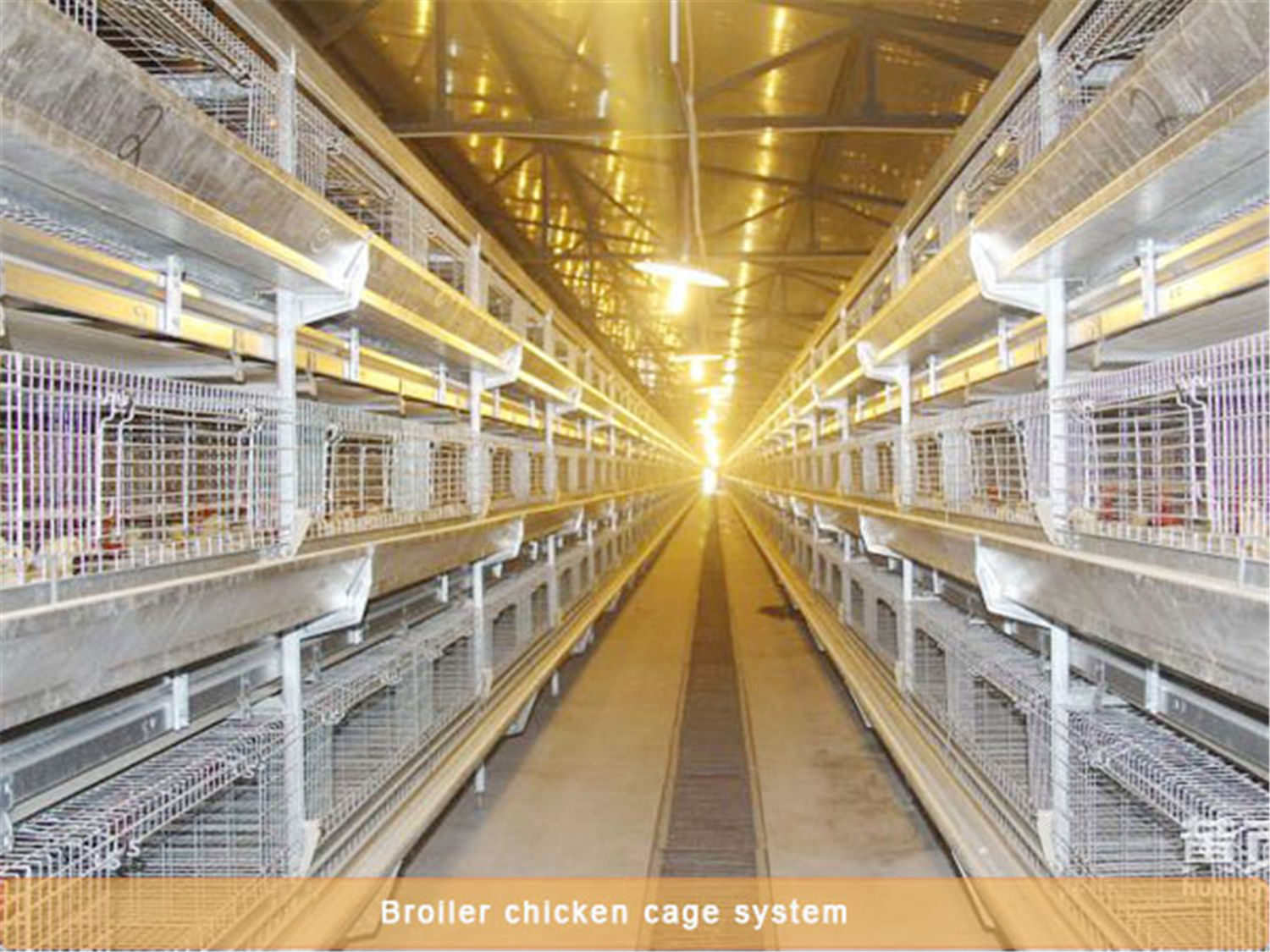

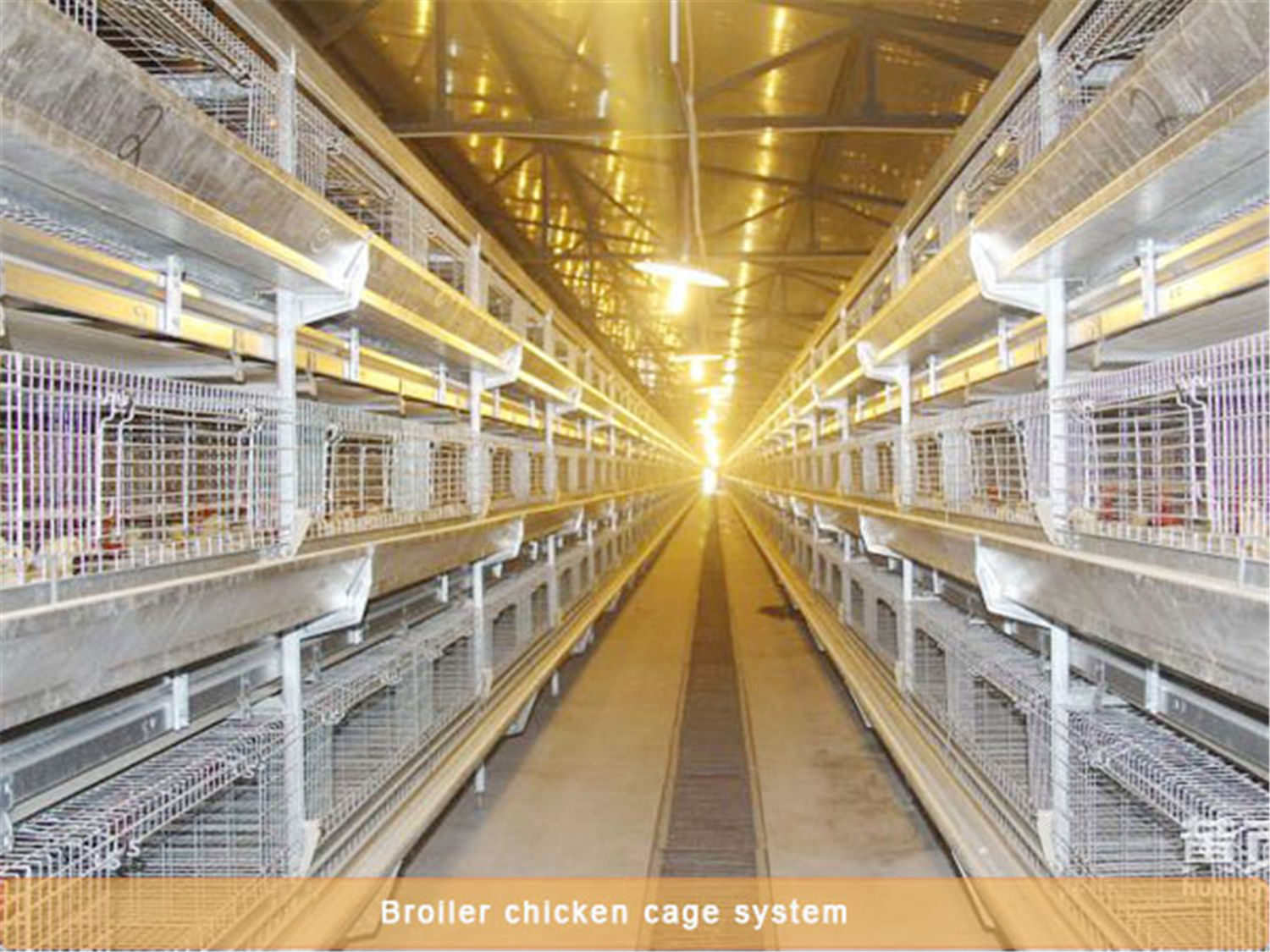

What are the advantages of broiler cages?

Experiments show that the technical advantage of commercial broiler cages is significantly better than the flat to raise. Not only can increase the number of breeding, improve production performance, save production costs, bring significant economic benefits to farmers, but also save land resources, reduce environmental pollution, improve product quality, and create huge social benefits.

In recent years, a more advanced broiler breeding model, broiler cages, is quietly emerging. What advantages does broiler cages have?

The advantages of broiler cages are:

1. High level of automation: automatic feeding, drinking water, decontamination, wet curtain cooling, centralized management, automatic control, energy saving, reduced labor costs, greatly improving the breeding efficiency of farmers.

2. chicken flock prevention, effective prevention of infectious diseases: chickens do not touch the feces, can make the chickens grow stronger, provide a clean and warm growing environment for the chickens, the chickens are healthy and balanced.

3. Compared with the flat raise, the density of the stock is increased by more than 3 times, the utilization rate of the surface area of ??the house is improved, and the land can be saved.

4. Saving feed: meat cages increase the growth rate and feed conversion rate, chickens are kept in cages, the amount of exercise is reduced, energy consumption is less, and waste materials are reduced. According to the experiment, cage cultivation can effectively save more than 25% of the cost of farming. The ratio of feed to meat in net or flat chicken is generally between 1.75 and 1.8:1, while the ratio of caged meat to meat is at least 1.61:1 and the highest is 1.7:1.

5. Reduce the cost of medicines, at the same time can effectively control the occurrence of the disease, because the chicken does not touch the feces, and the use of closed houses, isolated from the outside, reduce the spread of disease; indoor comfortable environment is also suitable for the healthy growth of chicken.

6. Save time: It is convenient for breeding users to manage livestock and poultry, saving more time to deal with other things; using a fully enclosed and fully automated farming mode, two people can manage a chicken house with 3-4 million chickens, which is very economical. Artificial.

Therefore, on the whole, the advantages of cage farming benefit are more and more obvious. In the previous model of land raising and net broiler chicken, the profit of broiler farming was less and less, and many large-scale farming or group with funds, even small-scale Farmers have changed their own chicken houses into cages to further increase the scale and land utilization rate, and improve the breeding efficiency through scale effect.

How to raising broiler chicken using automatic chicken equipment?

Nowadays, automatic chicken raising equipment are emerging in endlessly. Many farmers will rely on some automatic chicken raising equipment to raise broilers to improve work efficiency and reduce labor intensity. Although chicken raising techniques and methods have improved, many farmers still cannot get good benefits. In order to help the majority of farmers improve their scientific management level and achieve better economic benefits, let’s discuss some things that need to be paid attention to when using automatic breeding equipment to raise chickens.

- Choose the automatic chicken raising equipment that suits you: Among the modern chicken breeding equipment, the types of automatic chicken raising equipment include: automatic feeding machine, automatic manure cleaning machine, automatic egg picker, fan wet curtain, automatic drinking water equipment, etc. Commonly automatic chicken raising equipment, farmers can choose the required automatic chicken raising equipment according to their actual needs and capital budget to assist in raising chickens, and improve the efficiency of chicken raising.

- Learn to operate modern automatic chicken farming equipment: it is a relatively large-scale mechanized equipment that requires operation and maintenance. Therefore, whether it is operated by the farmers themselves or by the staff, they must pay attention to learning the correct operation method. Different equipment operation methods are It is not the same. Only reasonable and scientific operation can ensure the good effect and efficiency of the equipment, and can guarantee the life of use, and also pay attention to regular maintenance and maintenance of the automatic chicken breeding equipment, so that the problem can be found in time Timely solution these problems can guarantee and extend the service life of the equipment.

- Maintain the environment of the chicken house: the chicken coop is well maintained, and the chicken flock can reduce the occurrence of diseases. Because the chicken house has chicken flocks and some automatic chicken raising equipment, there will be a lot of manure, feed, dust, ammonia and other pollution. The existence of materials and harmful gases will seriously affect the health of the chicken flock. Therefore, if you want to ensure the sanitary environment of the chicken house, it is necessary to clean, disinfect and ventilate frequently. If you do these three points, you can maintain the hygiene of the chicken house.

The main points of how to raise chickens using chicken raising equipment are described for the majority of farmers. It is also a few tasks that farmers need to pay attention to in the process of raising chickens. I hope that the above description can help the majority of farmers to raise chickens in a scientific and reasonable manner. Improve economic efficiency!

Advantages and Disadvantages of Broiler Ground Thick-bed Feeding Slat

The broiler ground thick litter feeding refers to feeding 5-10 centimeters of litter on the ground of a strictly sterilized chicken house, and the entire period of growth of the chicken is fully maintained on the litter. The litter requires soft, dry, strong water absorption, is not easy to compact, does not mold, no pollution. During the rearing process, loosening of padding material, removal of wet litter, and addition of new litter should be made as appropriate.

Advantages: Suitable for broiler growth and development, slightly lower than the Internet temperature during the hot season. Usually do not remove the feces, do not change the litter, save time and labor; in the winter can use litter fermentation heat production and increase Shewen; chicks in the litter activity increased, reduced the incidence of earthworms. Easy to use, low equipment investment, low incidence of breast cysts, and low defective products.

Disadvantages: It requires a lot of litter, repeated investment. The management of litter is difficult. If the management is not good and the litter is wet, various diseases of the digestive tract and respiratory tract infections are prone to occur: such as E. coli, coccidiosis, and chronic respiratory diseases. Direct contact between chickens and feces, the incidence of coccidiosis increased, and other infectious diseases are prevalent. The contradiction between ventilation and heat preservation is prominent, and health management is difficult. Chicken manure use value is reduced.

Do you Know What’s the new Concept of Broiler Rearing Management?

With the progress of the times and the development of science and technology, the genetic breeding technology of broilers has been greatly improved, and the nutritional formulation of chicken feed has also undergone new changes. Broiler breeds are constantly being optimized, and the feeding and management viewpoints of broiler chickens are no longer practical. The broiler breeders at this time need to understand some new ideas for the early feeding and management of broilers.

Do a good job of early feeding chicks, so that the chicks get even and good development in the first week. Changing the way that chickens were fed before drinking water for a period of time before they were fed will become better when the chicks arrive. Change the practice of distributing drinking fountains according to the number of chickens in the past, and increase the number of drinking fountains accordingly so that the chicks can easily find the water in the column after entering the house. If the chicks do not use the trays within the first day of arrival, use clean plastic cloths on the net or spread clean and hard papers to spread the material on the chicks for feeding. The effect is much better than using the trays alone.

Precautions for automatic feeders

The production and use of automatic feeders greatly solve the problems of large and medium-sized farmers who are difficult to feed the chickens in chicken battery cages, have a long time and labor intensity, and effectively improve the work efficiency. Then the automatic feeder should pay attention to the use. What are the matters?

What are the precautions for using the automatic feeder?

First, pay attention to timely inspection. The inspection is divided into three parts: the top of the feeder, the belt, and the motor. The automatic feeding machine can not place heavy objects on the top, and check whether the belt is loose. The main part of the feeding machine is the motor and the geared motor. Therefore, pay special attention to whether the motor has abnormal conditions, and if necessary, handle it in time.

Second, we must pay attention to clean up. Because the dust will be generated during the operation of the feeder due to the production of feed, if the dust remains on the machine, it will cause dust in the control box of the feeder, which may eventually lead to short circuit and affect the machine. Therefore, when using, remember to regularly clean the feeder.

Third, keep the lubrication between the feeders. If there is no lubrication between the gear chains, the components inside the feeder will wear out, which will affect the working effect and efficiency.

Problems to be overcome in using broiler cage equipment to raise chickens

The use of broiler chicken cage equipment is the development trend of broiler breeding. More and more chicken farmers have begun to try to adopt the mode of broiler cage breeding, which is currently one of the advanced production methods in the broiler breeding industry. It has the advantages of saving land resources, improving breeding conditions, improving production performance, and reducing disease incidence. However, in order to achieve greater economic benefits, it is necessary to overcome its existing problems and maximize the benefits of broiler cages.

The main technical characteristics of broiler cages are as follows: First, the three-layer overlapping cage technology is adopted. The second is to be equipped with an automatic manure removal conveyor belt to clean manure in time and reduce harmful gases such as ammonia and sulfur dioxide in the house. The third is that the entire cage is made of hot-dip galvanized metal anticorrosive materials, and the bottom of the cage is covered with wear-resistant and corrosion-resistant plastic nets, which can effectively reduce the incidence of breast cysts and leg diseases in broilers. Fourth, the chicken house is fully enclosed, relying on air intakes and exhaust fans on both sides of the house to maintain air quality in the house. The staggered installation of incandescent lamps reasonably realizes artificial lighting, and the use of water heaters, wet curtains, and automatic spray devices to achieve temperature and humidity control in the house.

Experiments show that the technical advantages of commercial broiler cages over online breeding are very significant. Not only can increase the number of breeding, improve production performance, save production costs, and bring significant economic benefits to farmers. It can also save land resources, reduce environmental pollution, improve product quality, and create huge social benefits. In line with the development requirements of "scale, standardization, industrialization, and ecologicalization" of the broiler breeding industry, the widespread promotion and application will help accelerate the process of standardization and transformation of livestock and poultry farms, and effectively promote the upgrading of the livestock industry.

Although cage breeding has significant technical advantages over online breeding, there are still some problems with cage breeding technology, mainly in the following three aspects. One is that the initial investment of cage culture is larger than that of online culture, but because the profit rate of cage culture is much higher than that of online culture, the return is quick. Second, the technical requirements of cage breeding are higher than that of online breeding. Because cage houses are closed and fully automated, technicians must not only master breeding management techniques, but also be familiar with the operation of modern equipment. Third, the ventilation requirements of cage breeding are higher than that of online breeding. Because cage breeding is multi-layer breeding, it is more dense than online breeding, which easily causes poor air circulation in the house. Therefore, the above three points are the problems that farmers who use broiler farming cage equipment to overcome.

Precautions for purchasing broiler cages in Nigeria

Many farmers are purchasing broiler cages. Pay attention to some purchase matters.

First of all, we must know the distance between the iron bars of the broiler cage. This is very important for broiler cages. A reasonable spacing is 2.5cm*5cm. Some farmers may think that the size of the broiler chickens is relatively large, and the spacing can be increased. This idea is wrong. Conditional farmers can also lay a plastic net on the bottom of the broiler cage that is consistent with the cage eye. This can not only buffer the strength of the eggs hitting the net and reduce the rate of broken eggs, but also prevent some diseases.

The design angle of the bottom of the broiler cage. The angle of the broiler cage must be accurate. The egg cannot be rolled out in time at a small angle, and it is trampled by the chicken. A large angle may cause the egg to break, and the general angle is maintained at seven to eight degrees.

Pay attention to the connection between the broiler cage and the bottom of the cage net. I must remind you that there are farmers, and you can't leave a big gap here. Because there are more eggs here. You must pay attention to this detail when buying a broiler cage.

The choice of materials for the chicken cage is very particular. It is necessary to choose suitable and tough materials. The diameter of the iron wire at the bottom of the cage is about 2 mm. The egg breaking rate is very small. The larger the diameter of the iron wire, the easier it is to cause broken eggs.

Due to the high density of broiler cages, it is not conducive to observe the situation in the flock. Especially in the brooding period, it is more obvious, so it is necessary to carefully observe the cage around the cage carefully. Prevent the abnormal situation in the flock from being discovered and dealt with in time. When the chicks are just transferred to the rearing cage. Due to the new environment, the chickens will be temporarily uneasy. The chickens that ran out of the cage should be caught in the cage in time, and the chickens should be carefully checked for damage and whether all the chickens can drink water in time.

In addition, in daily management, we should carefully observe the chickens every time, and be well aware of the chickens’ feeding, drinking, feces, mental state, etc., timely prevent diseases, strengthen management, and reduce economic losses.These are the precautions for purchasing broiler cages in Nigeria

More...

Why buy high-quality broiler cage equipment?

Broiler cage equipment and caged chicken equipment are directly related to the efficiency of the farmers. Many chicken farmers' brooding, rearing and layer houses are out of proportion. And they do not meet the requirements. The rearing area is often too small, the rearing density is too large, and the feed and drinking troughs are not enough. It can be said that this is a common problem common to chicken farmers, and it is also one of the important factors affecting the economic benefits of laying hens. There are also chicken farmers who raise more chickens, use fewer houses or have no extra houses for chickens. Putting the chicks into cages prematurely is unfavorable to the growth and development of the young and will eventually affect the laying performance of the hens. For laying hens, the harvest is after the hens start to produce.

The equipment for raising chickens is inferior and mismatched. The equipment for raising chicks, brooding chickens and laying hens has specifications and ratio requirements. The equipment should be matched to facilitate the normal growth and development of the chicken group and reasonable turnover, and give full play to the utilization and operation rate of the equipment, so that the depreciation expenses allocated to each hen or each kilogram of eggs can be more reasonable, thereby reducing Cost of production.

Nowadays, laying hens are mostly raised in cages, and chicken cages are indispensable equipment, and chicken farmers generally pay more attention to it. However, they lack the ability to discern the quality of chicken coops, and tend to be low-priced when they are purchased. Cage is a place for hens to live, produce and sleep. Its quality cannot be ignored. The quality of the bottom of the cage, the width and slope of the cage are especially important. Another common problem worth noting is that chickens are not installed in cages. When the brood survival rate is high, the number of surviving hens exceeds the budgeted transfer number, or the hens that are too light are reluctant to eliminate hens that are too light. In this case, they are often overloaded. According to statistics, when the number of hens per cage increased to 5, 22.5% of the hens died before 305 days of age. According to the production report statistics accumulated by the author over the years, the egg production rate of chicken flocks whose cage density exceeds the prescribed standard is 5% to 15% lower than that of normal chicken flocks.

Therefore, the purchase agency can not only talk about cheapness, but needs to consider quality first

Main points of feeding and management of using broiler cages to raise chickens

For broiler breeding, most farmers now use broiler cages for breeding. The use of broiler chicken cages to raise chickens is more conducive to the management of the chickens by the farmers, and it is also more conducive to the rapid growth of the chickens. However, if the farmers do not use scientific and reasonable breeding methods to raise chickens, it will be difficult for the chickens to grow well. Today, I will give a detailed account of several key breeding points that farmers should pay attention to when using broiler cages to raise chickens.

1. Group the chickens

When the three-dimensional broiler cages are used to raise chickens, they usually use whole sports chicks. When the density of chicks is too large, group them in a timely manner to ensure that the weight of the chicks is even. The first grouping is usually 12-16 days old. The grouping is too early. It is easy to drill through the gaps in the growing cage, and it will cause a waste of space and energy. The second grouping, at 25-28 days of age, this time grouping should place the heavier healthy parts in the lower layer, leaving the weak young. In summer, because the temperature is too high, grouping can be carried out in advance. In winter, the temperature is cold and the temperature difference between the upper and lower cages is large. You can appropriately delay the time of cage division, and put one more in the lower cage to reduce the temperature difference between the upper and lower cages.

2. Control of temperature

When the temperature outside the chicken house is lower, the temperature difference between each layer is greater. Under normal circumstances, brooding are placed on the highest level, because the highest level has a higher temperature, which is conducive to saving heat. On the first day the chicks enter the farm, the temperature should be controlled at 33-34°C, which can also be adjusted according to the state of the chicks. When the temperature is right, the chickens are evenly distributed, lively, and have a strong appetite. When the temperature becomes low, shrink the neck and bow back and concentrate on the heat source. Squeezing each other, their bodies tremble. When the temperature is too high, water consumption increases, appetite decreases, breathing speeds up, and there is water in neck feathers. In the first week, the temperature dropped to 30°C, and then dropped by 2°C every week thereafter. The use of chicken cages to raise chickens has a high density, which is 1 to 2°C lower than the normal temperature. It is necessary to avoid the phenomenon of heat stress in the flock that causes a decrease in feed intake.

3. Disinfect the chicken house

The chicken house should be thoroughly cleaned and disinfected 5 days before the chicks are put into the house. Here, the farmers need to pay attention to avoid using caustic soda and other corrosive disinfectants for disinfection. After the chicks are in the house, the ground is cleaned every day, and the chickens are disinfected every other day.

4. Drinking water for chickens

After the chicks are placed in the house, it is necessary to ensure that they can drink clean and sanitary water within 2 hours. For the first time the chicks drink water, use warm water at 25°C, add 5% glucose and 0.1% vitamin C to the water, and rinse the drinking fountain frequently. Drinking water should not be interrupted throughout the brooding period. From the second day of brooding, add drugs to prevent pullorum in the drinking water.

The above is the summary to the farmers today, in the process of using broiler feeding cages to raise chickens in Uganda, the main points for the management of chicken flocks. I hope that through today's description, farmers can pay more attention to these points in their future breeding work.